- Mon-Fri | 8:30 - 5pm GMT

- +44 (0)1727 874444

- [email protected]

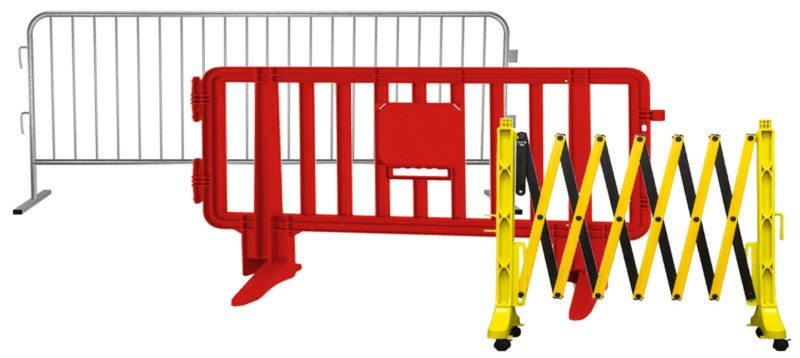

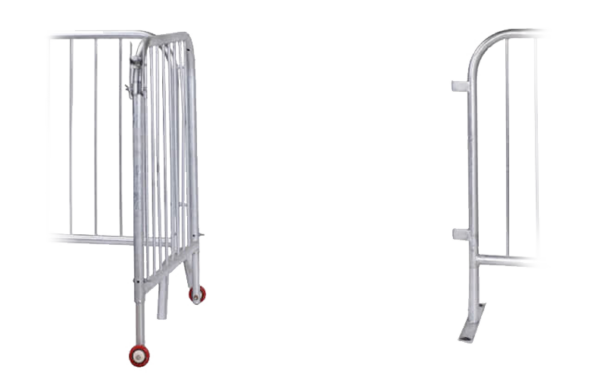

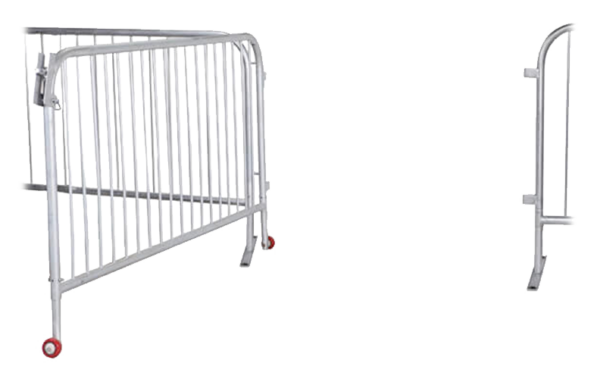

CrowdMaster

1M BARRICADE GATE

- Pedestrian Access

- 1m Length

- Hot Dipped Galvanised

- Hook and Loop Fastening System

Colour Barricades

1.8M COLOURED BARRICADE SILVER

- Heavy Duty 16 Gauge Steel

- Powder Coated

- Weather Resistant

- Four Base Options

1.8M COLOURED BARRICADE RED

- Heavy Duty 16 Gauge Steel

- Powder Coated

- Weather Resistant

- Four Base Options

1.8M COLOURED BARRICADE YELLOW

- Heavy Duty 16 Gauge Steel

- Powder Coated

- Weather Resistant

- Four Base Options

1.8m COLOURED BARRICADE GREEN

- Heavy Duty 16 Gauge Steel

- Powder Coated

- Weather Resistant

- Four Base Options

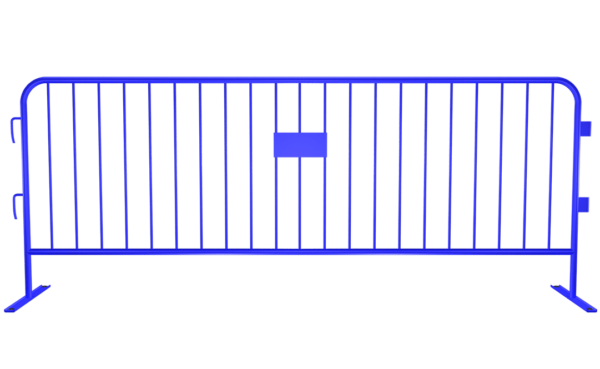

1.8M COLOURED BARRICADE BLUE

- Heavy Duty 16 Gauge Steel

- Powder Coated

- Weather Resistant

- Four Base Options

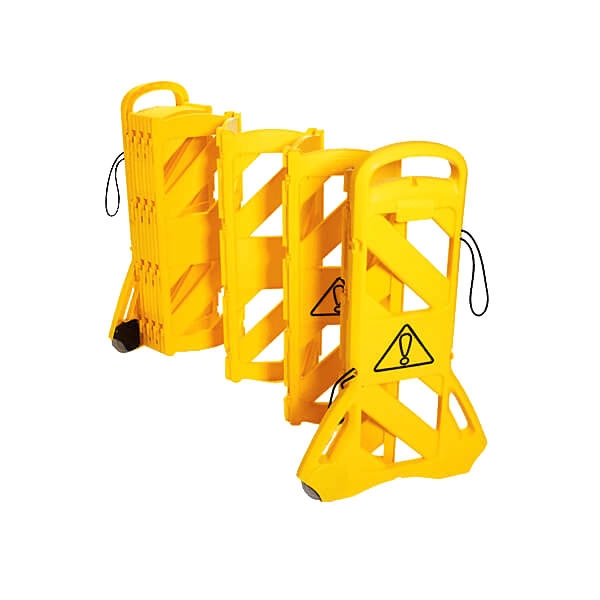

Plastic Barricades

Expanding Barriers

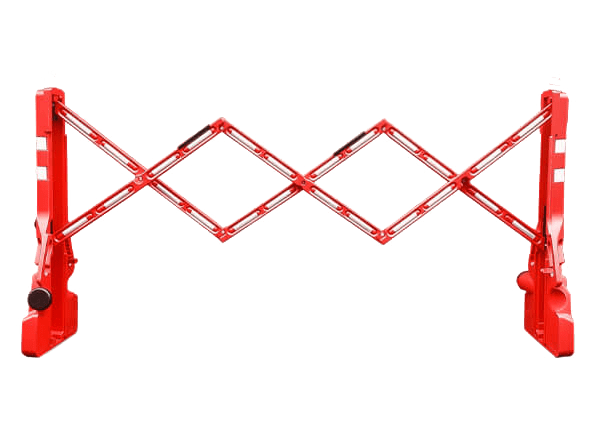

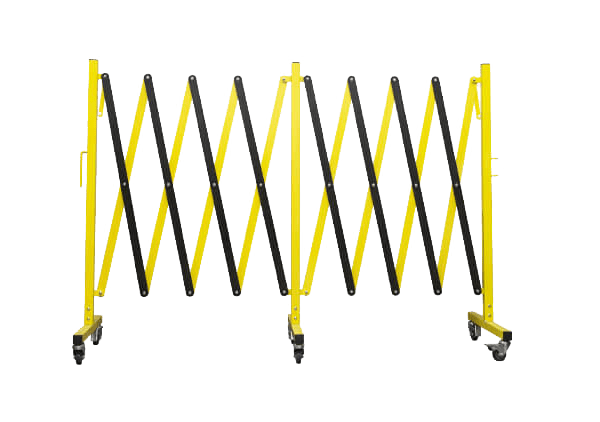

EXPANDABLE MOBILE BARRIER

- Lightweight

- Fully assembled

- Locking Straps

- 3.9m Expandable Length

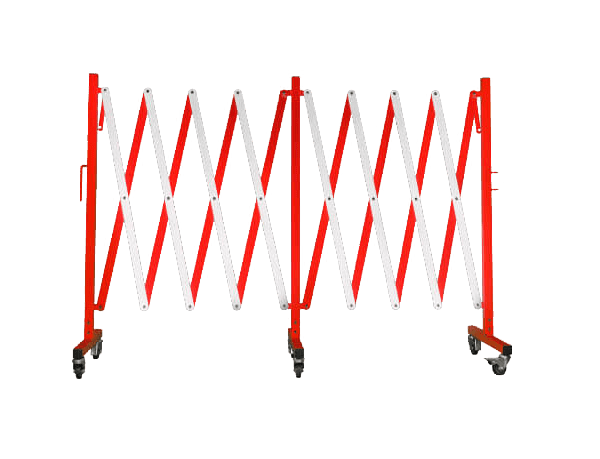

FLEXPRO 160 RED WHITE

- Easy Storage

- Interlocking Design

- Red/White Colour Option

- 4.9m Expandable Length

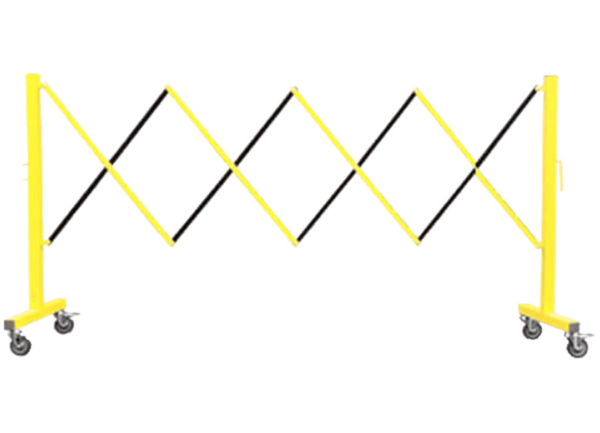

FLEXPRO 160 YELLOW BLACK

- Easy Storage

- Interlocking Design

- Yellow/Black Colour Option

- 4.9m Expandable Length

Barricade Accessories

What is a Barricade?

The dictionary definition of a barricade is “any barrier that obstructs passage”, however in the crowd control industry the term barricade is typically used to define a rigid, heavy-duty barrier usually made of steel or plastic. This type of barricade is sometimes called a “bike rack barricade”. A barrier is generally considered to be a lighter more flexible item such as a retractable belt stanchion or polyethylene “police tape”. Barricades are used for controlling large crowds most often in outdoor venues. Barriers are typically used indoors and guide rather than control pedestrian flow. The design and manufacturing of barricades is dictated by their use. Being used outdoors for large crowds requires barricades to be manufactured with a high degree of strength to withstand crowd pressure and they must have excellent weatherproofing for permanent outdoor use. Finally, as most crowd control applications are temporary barricades need to be portable as they are set up for specific events and removed afterwards. The constant movement and stacking of barricades is another reason they need robust construction.

Plastic or Steel Barricades

In selecting either plastic or a steel barricade you must consider how the barricade will be used. Plastic offers the advantage of lighter weight making the setting up, taking down and transport of the barricades easer. Steel is heavier and will provide a better barrier for very large crowds and over time will be more durable than plastic.

Barricade Features

When comparing barricade brands before ordering there are features you should consider before making your purchase decisions. Here is a quick guide to the key barricade features.

| FEATURE | DESCRIPTION | NOTES |

|---|---|---|

| Hot Dip Galvanising | A weatherizing process in which the barricade frame is dipped in a tank of galvanising solution. | Offers the highest degree of weather protection and is very resistant to abrasion damage |

| Pre-Galvanising | The components of the barricade are galvanised before assembly. | Lower cost but gives less weather protection. Can be used outdoors but should be stored indoors. |

| Powder Coat | Pigment is applied in powder form and then baked in a high temperature oven. | Allows barricades to be colored. More durable than paint, suitable for extended outdoor use. |

| Steel Gauge | Thickness of the steel. Heavy duty is 16-gauge, light duty 18-gauge. | Both thicknesses make strong barricades, but 16 gauge will be more durable. |

| Upright (riser) count | Also known as risers, the thin bars between the outer frame tube. | The closer spaced the uprights the stronger and more rigid the barricade. High spec barricades typically have 20-21 uprights, low spec brands can have as few as 14. |

| Flat Feet | Low profile feet that are flush with the ground | Low trip hazard, designed for flat surfaces like tarmac or concrete. |

| Bridge Feet | Bridge shaped feet. Supplied as one large and one small so the barricades can be set at right angles. | Use for rough or uneven surfaces such as grass or gravel. |

Welding

In addition to the above features pay particular attention to the welding before making a purchase decision. Be sure that the uprights are fully inserted into the frame before welding as that maximizes the weld strength. The uprights on cheap barricades are often tack welded to the surface of the frame and will break causing the barricade to flex. Similarly, where the frame tube is welded make sure the frame is saddle cut and the tube inserted before welding.

Barricade Accessories

There are several accessories available that improve the versatility of barricade and add branding opportunities.

Barricade Carts

A simple means for transporting and storing barricades. Carts are available with 10, 28 and 30 barricade capacities. Models are designed to be manually pushed or pulled or to be hitched to a forklift for towing.

Swing Gates

Gates provide access through a line of barricades. Attached using the same hook and loop system as the barricades, the gates have a latch that will hold them securely when closed. The small 38” gate provides pedestrian access while the large 79” gate is for vehicle access.

Jackets

Jackets are an ideal way to turn barricades into highly visible billboards. Made from heavy duty vinyl and attached by Velcro flaps, jackets can be custom printed with any logos or branding desired.

Conclusion

Barricades are ubiquitous crowd control products seen everywhere large crowds need guidance and control. Although barricades look the same a closer examination will show a wide variety in specification and build quality. It is well worth the time to look closely at the features listed above when comparing brands. Making an informed choice will result in purchasing a barricade that will give a longer service life and ultimately a lower lifetime cost.

Frequently Asked Barricade Questions

Q: Do Steel Barricades Come In Different Colours?

We offer a wide range of high visibility colours specially tailored for site safety such as yellow, orange, and red.

Any of our steel barricade can also be custom powder coated to match a specific Pantone colour. Our smart colour match technology allows for colour matching to best represent your brand or organisations.

Q: Are your Steel Barricades weatherproof?

A: Our hot-dipped galvanised & powder coated steel barricades are highly weather resistant and can stand up to hard weather conditions. Add powder coating to our hot-dipped galvanised barricades to add an additional layer protection from the elements.

Steel Barricade Finishes

Hot Dipped Galvanised Steel Barricades: These steel barricades are hot dipped after welding. Our technicians dip the finished product as a single piece of steel, allowing for galvanisation of each join, this process creates the most durable product.

Pre-Galvanised Steel Barricades: These steel barricades are hot dipped before welding. Each component is galvanised then welded together. This process cuts down on cost but sacrifices some durability since the joint are no fully galvanised. These barricades are not designed for prolonged or frequent outdoor use.

Powder Coated Steel Barricades: Our powder coating process creates a colourful barrier around the barricade. Beyond the aesthetics of the powder coat colour, the additional layer of durable pigment increases the durability of the barricade. Powder coated steel barricades are frequently used outdoors for limited periods of time. Pair our powder-coating process with our hot dipped galvanised barricades for additional durability.

Q: How do the barricade feet work?

Types Of Steel Barricade Feet

Flat Feet: Ideal for levelled terrain such are sidewalks and tarmacs.

Bridge Feet: Ideal for uneven terrain such as grass and gravel.

Heavy Duty Feet: Designed for harsh environments, these feet provide the most durability and longevity

Roller Feet: These steel barricade feet allow add more flexibility to standard barricades. With a specially designed wheel barricades can be dynamically relocated by a single person.